Tea Manufacturing

Steps of Tea Manufacturing

- Withering of Green leaf

- Process of Rolling

- Roll Breaking

- Fermentation

- Black Tea Drying

- Sifting and Grading

Plucking green leaves

Green tea leaves are the only ingredient used in the tea manufacturing. Quality of the end product mainly depends on the quality of the Greenleaf used for manufacture. In order to bring good tea leave from the field to factory, the following points should be carefully focused.

- Plucking Standard

- Severity of plucking

- Frequency of plucking

- Yield

After plucking tea leaves from the field, they should be taken to the tea factory as soon as possible in order to minimize post-harvest damage. It is possible to make good quality made tea from those tea leaves.

Withering of Green leaf

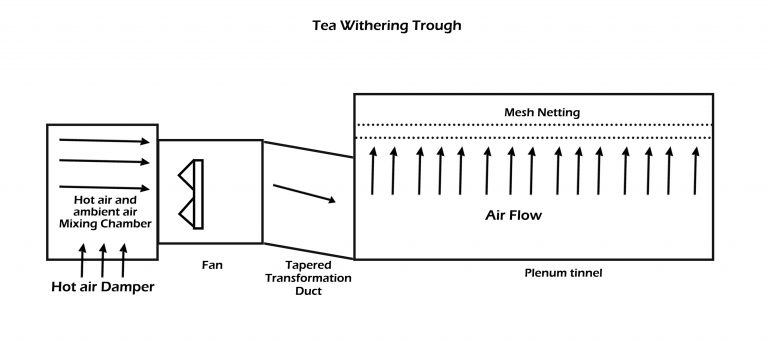

The major physical changes in Greenleaf during watering are removing moisture softening to suit the rolling process in tea manufacturing. There are three main types methods used to wither Greenleaf in tea factories. Those are Tat Withering, Trough Withering and Drum Withering. Trough Withering is commonly used in black tea process of above three methods. Below is a photo of an outline of a commonly used withering trough.

The General Spreading rate is 2.5kg for square feet and 22 CFM are given per 1kg of Greenleaf. The withering is to remove only moisture in the Greenleaf by using hot air and ambient air under controlled conditions .The Intensity of withering depends on the percentage of moisture removing. The percentage of moisture in each stage is as follows

- Greenleaf 80%

- Withered leaf 55%

- Made Tea 3%

Objectives of Withering

The main objectives of the withering process can be divided in to two main categories.

- Physical Withering

- Chemical Withering

Physical Withering

- Removal of moisture from the leaves

- Leaf becomes rubbery stage (flexibility )

- Increasing the permeability of cell membranes

- Weight loss

The above changes make leaf suitable for next process of rolling without breaking into small pieces.

Chemical Withering

- Increasing the concentration of amino acids in the leaf

- Activating enzymes

- Increases caffeine amount

- Organic acid levels nary

- Increases fat an glucose levels

- Increases the amount of carbohydrates

It takes 7 to 9 hours to takes place the above mentioned biochemical changes in the withered leaf.

Process of Rolling

The tea roller primarily breaks the walls of cell in withered leaf during traditional rolling process. In this process, polyphenol (catechins) and polyphenol oxidase enzyme, which are present in different layers reacts with oxygen and oxidation process begins. In addition the tea leave are twisted and broken in to pieces as needed. The rolling room should be maintained at approximately saturated air during this rolling process. There is a picture of traditional tea roller below.

Factors required getting good rolled leaf

- Supply of tea leave according to the roller capacity

- Apply right pressure

- The rolling table is equipped with the battens

- Controlling temperature

- Loading evenly withered leaf

- Keep the machine clean

C.T.C(Lawris Tea Processor)

C.T.C means Cut, Tear and Curl. The machines used in this tea manufacturing method works very fast and tea leaves are cut vigorously. In that case, polyphenol (catechins) and polyphenol oxidase enzyme, which are present in different layers reacts with oxygen and oxidation process begins. The made tea produced from this process has a good colour and astringency, therefore made tea from method is mostly used for tea bags. But due to severe cuts made in this process, the natural flavour in the tea are often damaged.

Rotorvane

This machine is grinder used to make traditional orthodox tea. In this Process this machine is used as a second roller then rolled leaf is broken into smaller piece. Therefore, tea quality of tea made in this method is relatively high. The diameters of barrel of rotovane commonly used are 8, 12 and 15 inchers. There is a strong demand for this in the international market.

Roll Breaking

This machine separates the rolled leaves according to their size. If size of rolled leaf lager thab the required size are again crushed by the roller. There are two main type of machine used for rall breaking, those are rotory roll breaker and reciprocatory roll breaker. The following are main purpose of rall breaking.

- Separating rolled leaf according to the size

- Facilitation of oxidation

- Control the temperature develop by rolling process

- Removal of nodule during the rolling

Fermentation

The purpose of fermentation is to develop taste of final tea cup by causing the necessary chemical changes in the rolled leaf. The colour, taste and flavour of the tea cup are the result of a complex chemical reaction that takes place during the fermentation process. In this process polyphenol reacts with oxygen in air and oxidation process takes place and Theaflavin , Thearubijin and fragrant ingredients are formed.

Factors that deepens on the intensity of fermentation

- Temperature of dhools

- Fermentation period

- Enviroment Humidity

Black Tea Drying

Drying is a very critical step pf tea manufacturing. The purpose of drying tea is to stop the process of fermentation at the optimum level. For this purpose, the fermented dhools (rolled tealeaf) are exposed to very high temperature. During the drying process, the moisture content of the tea is reduced to three precent. From this made tea has ability of storing .It use odourless hot air currents to dry dhools. Normally petroleum or firewood is used to produce this hot aircurrents.Below are two commonly used tea drying machines.

- ECP (Endless Chain Pressure Dryer)

- FBD(Fluid Bed Dryer)

Sifting and Grading

Sifting and grading is the last step of the tea manufacturing. The main purpose of tea sorting is facilitating sales. In the sifting of tea, the main thing is to separate fired tea (dried tea) according to the heir size and blackness. In this process also removes the fiber in the fired tea. Produce different grades according to methods of Orthodox leaf Othodox rotorvane and CTC. Normally the moisture content should be around five precent at the time of packing the graded tea.

Machine used in Sifting and Grading

- Chota

- Michie

- Myddleton

- Tarry Nipper

- Winnower

- Cutter

- Fibro mat