Tea Withering Process

Introduction to tea withering

Tea is one of the most popular beverage in the world and has many health benefits. Tea can be divided into several categories depending on the manufacturing process. The first step in the black tea production is tea withering process.

The withering of tea is basically a drying process where it removes moisture from internal and surface of freshly harvested green leaves. There are two major type of tea withering, natural withering (tat withering) and trough withering (artificial withering). Of these, the trough withering method is most widely using method because of it can be done under controlled conditions.

Two withering methods

- Tat withering – old method

- Trough withering – present method

Objectives of Tea Withering Process

This process can be divided on into two parts depending on how it takes placed.

- Chemical withering

- Physical withering

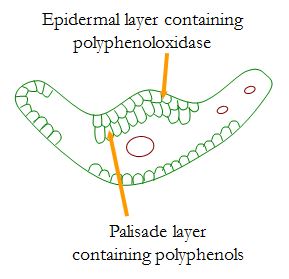

Chemical changes in the tea withering process

For the following chemicals changes to takes place, the tea withering process must take at least nine hours.

- Increases the concentration of the amino acids

- Increases the concentration of caffeine in the leaf

- Enhance the activation of enzymes

- Increases the amount of liquid carbohydrates

- Makes fat and glucose

- Organic acid levels vary

- Carotenoids converts to β-Ionone

- Chlorophyll breakdown

Physical changes in the tea withering process

The following changes make the tea leaves suitable for rolling in rollers without breaking into pieces.

- Reduces moisture content

- Increases the permeability of cell walls

- Increases flexibility of tea leaves

- Weight loss occurred

- Concentration of the cell sap

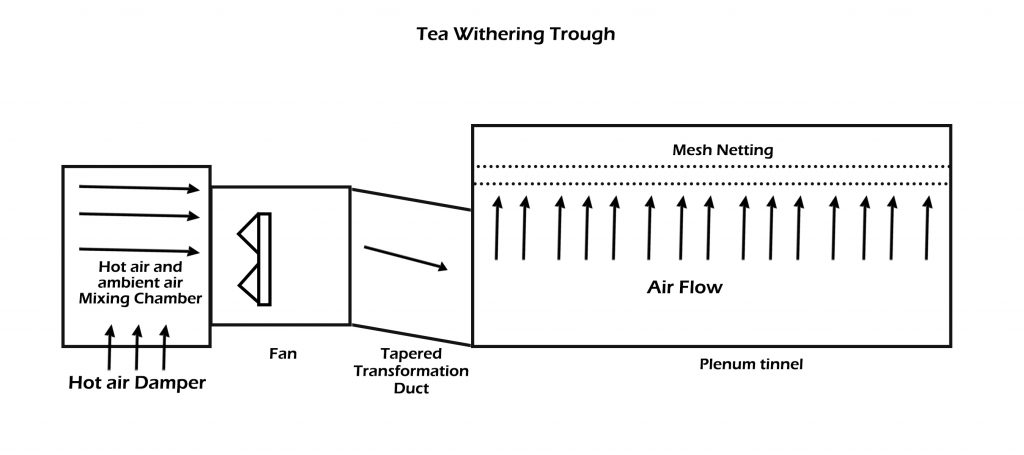

Trough withering

Recommended conditions for trough withering

- Use skilled workers.

- Follow the correct loading, loosening and turning practices.

- Avoid over loading and under loading the troughs

- recommended loading rate : 2.5 kg/sq.ft (2.0 – 3.0)

- Monitor efficient use of hot air for withering using hygrometer

-

- For wet leaves: 8 – 10oF (until surface moisture is removed)

- For dry leaves: 4 – 6oF

- Maintain dry bulb T ≤ 90oF

-

- Recommended flow rate of air: 20 cfm /kg GL

- Proper loosening of leaves to break lumps is required

- Turning the leaves at correct time is important to get uniform wither.

-

- Single turning is adequate for dry leaves

- Two turnings are required for wet leaves

- Delaying turning leads to discoloration of leaves

-

Ensure proper function of hygrometers

- Place the hygrometers at the middle of the trough

- Check the water level

- Replace the old wick with new ones

- Ensure withering air is leaking through the

- Box and passing over the meter

- Avoid water dropping from the meter

- Cover the water container completely

Proper practices in tea withering process

- Turn the leaves at the correct time

- Operating the fan and supply air during loosening and turning at appropriate speed

- Avoid thin spreading in longer troughs

- Loosen the leaves twice in the case of wet leaves

- Use hot air at the beginning if necessary. Delay in hot air supply and low withering rate leads to packing

- Regulate hot air by monitoring the hygrometer

- Hot air supply must be managed properly to obtain wither in all the trough

- Avoid air pockets in leaf bed

The tea withering process is also very important in the tea manufacturing process for the quality of the final product. Therefore, it is very important to pay attention to the process of tea withering. Visit to read more Tea Manufacturing